Fuller Houses

R. Buckminster Fuller and his various Dymaxion Houses

Odds are you are familiar with Richard Buckminster Fuller: genius, polymath, humanist, philosopher, designer, architect. If you can’t place the name, all I have to do is say, “the inventor of the geodesic dome” and an image should start to form in your mind.

You are far less likely to be familiar with any of R. Buckminster Fuller’s actual work, because there is so very little of it. He was not an architect in the traditional sense of “a person who designs buildings,” but a visionary exploring the philosophy of architecture, engineering, and life through ambitious and experimental plans that would not, and sometimes could not, be built.

Fuller eventually made peace with the fact that he was a dreamer building castles in the sky, but that wasn’t always the case. Today we’re going to talk about his early years, when he made several attempts to be a traditional architect — or as traditional as it was possible for him to be. None of these attempts ended well, and they all had one thing in common that contributed to their spectacular failures.

That one thing was R. Buckminster Fuller.

Stockade Building Systems

Richard Buckminster Fuller was born in Milton, Massachusetts on July 12, 1895.

He seems to have been an intelligent young man with no particular direction in life, with an enormous ego and a knee-jerk hatred of anyone who tried to tell him what to do. Family connections got him into Harvard but he was expelled twice, first for a wild night of debauchery and then for skipping classes. He could only find employment as an unskilled laborer, first in a textile mill, and later in a meatpacking plant.

During World War I he was drafted into the Navy, and that brush with military discipline seems to have done wonders for his attitude. At the very least he learned how to hide it, and had the revelation that the way to avoid butting heads with authority figures was to become one himself.

In 1923 architect James Monroe Hewlett launched a new company called Stockade Building Systems. He had invented a new building technique, adapting industrial concrete masonry techniques for home construction by replacing cinder blocks with ones made out of compressed fiberboard. In modern business terms, his goal was to disrupt the industry by lowering the cost of construction materials and reducing the amount of skilled labor required. Hewlett was a busy man who couldn’t devote all of his time to managing Stockade, so he brought in a junior partner: R. Buckminster Fuller.

Hewlett did not hire Fuller for his technical expertise, because Fuller had none. He had never studied architecture or engineering, nor had he ever expressed the slightest interest in either field. That was okay, because the primary job of Stockade’s junior partner would be sales and marketing, helping overcome the natural resistance of the architectural establishment and building trades. Fuller had no particular experience in that field, either, but he did have far more important qualification: he was Hewlett’s son-in-law.

Over the next several years Stockade achieved some modest successes, furnishing building materials for over 240 homes and steadily growing until it had five regional sales offices. That wasn’t good enough for the company’s investors, and in 1927 they staged a shareholder revolt that forced Fuller out. Before you dismiss the investors as small-minded profit-seekers, it is probably worth noting that Fuller had a bad habit of acting like he was the company’s sole proprietor. He had set up several offices under his direct control, diverted company resources to his personal projects, and co-mingled his finances.

The next several months were the lowest point of Fuller’s life.

He was unemployed, penniless, and living in a Chicago slum. He was struggling with the death of his daughter Alexandra and stressed by the birth of daughter Allegra, and that put additional strain on his marriage. He began contemplating suicide.

One day, as he was wandering the shores of Lake Michigan and thinking about ending it all, he had a mystical vision where God commanded him to “discover what, if anything, an individual human eschewing politics and money-making can do effectively on behalf of all humanity.”

That was the turning point. Fuller now dedicated himself to this holy mission. To rid himself of every received opinion, untested assumption, and unthinking action he started meditating and stopped speaking for over a year. What emerged on the other side was pure genius.

That story is nothing more than salesmanship and self-mythologizing. The broad outlines are true, but Fuller had to make a lot of edits and omissions to make it work.

He actually went straight from his position at Stockade to a nearly identical one with the F.R. Muller Company of Waukegan. It paid less, but he had savings and could always rely on financial support from his father-in law. He was hardly living in a slum, unless you consider anything smaller than a mansion a slum. Alexandra had died years earlier and he had long since come to terms with her death. He certainly never spent a year in silent meditation, because nothing in the world could make the man shut up. I’ll leave it up to you to judge whether he had a mystic experience or not.

It was the turning point, though, and what emerged on the other side was pure genius. Of a sort.

Lightful Towers

Now, Fuller didn’t know anything at all about architecture when he started at Stockade but if he was going to disrupt the home construction industry it would help to know what, exactly, he would be disrupting. So he began studying architecture and quickly became a self-taught expert.

He soon began to question everything he had learned. This is pretty common with autodidacts. When you are immersed in a system you can sometimes have trouble distinguishing which rules are ironclad and which ones are just matter of culture or preference. The problem is when you are outside of a system all of the rules seem kind of arbitrary.

In Fuller’s case he thought Stockade’s revolution wasn’t revolutionary enough. It was content to address the methods of modern home construction without challenging its form or intent. He became determined to imagine what a truly revolutionary home might look like.

To accomplish that, he would have to do more reading and research.

He subscribed to architectural journals so he could understand how the industry thought. He attended trade shows and manufacturing fairs to see where technology was headed. He studied biology and ecology to see how organisms reacted to their habitat. And he read every philosophy text he could get his hands on.

One of those texts was Le Corbusier’s Toward a New Architecture, which had just been translated into English. The French architect’s philosophy resonated with Fuller, especially the exhortation to “close our eyes to what exists,” the conception of a house as a “machine for living,” and the demand that industry “occupy itself with building and establish the elements of the house on a mass-production basis.”

In fact, it resonated with Fuller so much that he swiped that philosophy for himself. In later years he even backdated his essays, diary entries, and correspondence so he could claim that these ideas had sprung from his own brow before he’d ever heard of Le Corbusier.

That take may be a bit too cynical. The idea that architecture needed to adapt to the needs of modern consumers as well as advances in science and industry was floating around in the ether. The most notable expression of the idea was a faddish interest in modular and prefabricated housing. Le Corbusier made repeatable floor plans that could be modified as needed. Walter Gropius and the Bauhaus experimented with houses made from a single pour of concrete into a gigantic mold, and Thomas Edison actually made the damn things a reality. Sears-Roebuck shipped construction kits across the entire country on rail.

Fuller took things in a different direction. Influenced by his background in sales and manufacturing he reframed the house as a consumer good, as mobile and portable and disposable as any other personal possession.

In his 1927 book Lightful Houses, Fuller proposed the creation of Lightful Towers, pagoda-like structures consisting of platter-like floors suspended from a central support mast. These would be manufactured with industrial efficiency on an assembly line, like an automobile or an airplane. Zeppelins would float them anywhere in the world, drop massive bombs to carve out their foundations, and then lower them into a crater along with a load of quick-drying cement. A series of standardized connectors would then allow the tower be hooked up to any service it needed: Artesian wells for water, septic tanks for sanitation, trash-burning incinerators for power.

Fuller estimated that the installation process would take eight hours from start to finish, and likened it to planting a tree. The whole process could also be reversed if you ever wanted to move and take everything with you. It was a revolutionary idea: a home which could be installed anywhere in the world, completely untethered to existing infrastructure and tied to its owner rather than to a plot of land.

Fuller’s hope was that these self-sufficient homes would create self-sufficient people. He imagined new homeowners flocking to his Lightful Towers, emptying out the inner cities and slums. In the short term the lowered population density would bring an end to crime and disease. In the medium term it would smash the entrenched power of the real estate market and lead to a more equitable economy and the death of materialism. In the long term it would create a better race of people who did not rely on the government, which would lead to its overthrow and the establishment of a utopian anarchy.

Like most Libertarian pipe dreams, it was also more than a bit mad. How, exactly, were slum residents who could barely make rent supposed to afford brand new homes? Off-the-grid self sufficiency sounds nice but can often be a logistical and financial headache. Emptying out the inner city wasn’t likely to cure all of society’s ills, and the mass decentralization Fuller was advocating for was just as likely to cause as many problems as it solved.

There was also the matter of practicality. Cargo zeppelins had always been a pipe dream and most people had given up on them by 1927. A single mass-produced home design was unlikely to be well-suited to all conceivable environments, though Lightful Houses showed Fuller’s towers being installed everywhere from the North Pole to the Sahara.

None of that really mattered, because the Lightful Towers were about as insubstantial as their name suggested. Fuller didn’t have blueprints, only concept drawings. There were a million questions that needed to be answered before they could become a reality.

The 4-D House

Fuller was working hard on converting the Lightful Towers into a viable product, though. He spent months drafting plans and crunching the numbers before he announced his solution. He flirted with a few names for it, including “the Cosmopolitan Home” and “the Lightful House”, before eventually settling on “the 4D House.”

There was no particular significance to the name, except that it sounded futuristic.

Anyone who had read Fuller’s book and was expecting to see a giant Jetsons-style stilt house was going to be disappointed, because from the outside the 4D House looked like a typical Beaux-Arts ranch home. Appearances were deceiving, though. Under the hood it was a house like no other.

The center of the 4D House was a sturdy column or mast like the one that had been central to the Lightful Towers. Modular room units were attached to this mast with high-tension wires and carefully balanced to maintain the equilibrium of the whole through counterbalancing stresses. New floors could be added to the house by extending the mast vertically and hanging new rooms from it. HVAC, plumbing, electrical wires and other utilities were run through the mast, simplifying the hook up to each module and reducing the need for specialized labor.

Because of the mast’s comparatively small diameter the house did not need a full foundation or slab, just enough topsoil or bedrock into which it could be embedded. As a result its overall footprint was minimal, and the house itself was portable as promised. All you had to do was disconnect the utilities, detension the wires, lift off the rooms, pluck the mast out of the ground, and truck everything to a new location.

By Fuller’s calculations when the house was ready for full-blown mass production it would cost as little to produce as an automobile on a pound-per-pound basis. By using lightweight materials he could get the weight of a 2,000 sq. ft. two-bedroom house complete with appliances down to about three tons, and a price of about $1,500. That was a bargain even in 1928, when the average home was selling for about $8,000.

Fuller wrote a fifty-page booklet about the house, simply titled 4D, then ran off a couple hundred copies and went to the May 16, 1928 conference of the American Institute of Architects in St. Louis to hand them out. He met with the board of directors, explained his revolutionary new idea to them, and then offered to donate the entire project and its associated patents to the AIA so the organization could lead architecture into a bold new era.

It did not go the way he had hoped. The AIA refused his generous gift, and passed a resolution opposing mass-manufactured, industrialized, and pre-fab housing.

The American Institute of Architects is opposed to any kind of house designs that are manufactured like-as-peas-in-a-pod.

Or at least, that was Fuller’s version of events.

It turns out he was not actually invited to the conference, but used his father-in-law’s good name and connections to crash it. He did not make a presentation to the board of directors. He may have met with some directors privately, but seems to have shot himself in the foot by coming off as a pompous egomaniac with delusions of grandeur. He had no patents to offer the AIA, because he hadn’t applied for them yet. While the AIA did pass a resolution decrying mass-manufactured housing, it was not a response to Fuller — it was passed at the start of the conference to help set the tone.

I don’t know why he expected a different reaction. He was asking architects who viewed their trade as an art or craft to change their paradigm to one which threatened their livelihood. That was a hard sell and Fuller, self-consciously superior and bloviating R. Buckminster Fuller, was never going to be the person who could make it.

Undeterred, Fuller expanded 4D into the book-length 4D Time Lock, adding new chapters about his philosophy and goals. He sent free copies to notable thinkers and industrialists like Bertrand Russell and Henry Ford. The near-universal reception was that people were intrigued by his ideas but found the writing so abstruse they weren’t quite sure what he was saying.

He finally applied for a patent on the 4D House in October 1928… and was promptly denied. It turns out all of the construction techniques which made the 4D House notable had already been developed by other people. Like his father-in-law, Fuller was merely taking ideas from industry and applying them to home construction, which was novel, but not exactly patentable. Sensing that there was little point in amending his application, Fuller dropped it completely.

He was also rejected by industry itself. At one point he met with ALCOA executives to discuss the possibility of using aluminum structural members in the 4D House. The executives laughed in his face, telling him that aluminum was unsuitable for construction because it came in two types, “soft” and “softer.” Of course, they then had to eat crow when stronger aluminum alloys came on the market a few months later.

(Once again, this is Fuller’s version of events. Duralumin had been invented by the Germans in 1909 and similar alloys were being used for any number of purposes. It seems more likely the ALCOA executives were laughing at Fuller’s naive belief that aluminum would somehow never corrode or degrade… though more about that later.)

If Fuller was going to revolutionize architecture, he was going to have to do so from the outside.

The First Dymaxion House

He decided he needed to take his idea to the public. The public, though, was going to be confused by his technobabble and nod off whenever he started philosophize. To capture their attention he would need something visually arresting.

In 1929 he sat down and built out a scale model of the 4D House. He made one small change, adapting the shape from the traditional square home in his patent applications to a hexagonal house with triangular rooms. Not only was it more futuristic-looking, the math for tensioning the wires and balancing the rooms got much easier the closer the plan got to circular.

The new 4D House was made out of modern materials like concrete, plastic, and aluminum which would require no maintenance and would never tarnish or corrode. It featured a bedroom, a bathroom, a living room, a study, and a combined kitchen/utility room. The floors were nothing more than taut wires over radiating beams, overlaid with tarps and pneumatic mats. He boasted you could drop a baby and it would “bounce, but… never break.” He jacked up the clearance underneath the floor so you could park your car underneath. Or maybe even your airplane if you were so inclined.

Then he took his show on the road, giving presentations about his new ideas for housing to anyone who would have him. He spoke to students at Harvard, he spoke to young architects at the Architectural League of New York, he spoke to policy wonks at the City Club of Chicago, he spoke to tradesmen at the Chicago Home Owner’s Exhibition, he spoke to bohemians at Romany Marie’s tavern in Greenwich Village.

The most impactful of these, though, was an invitation to speak at Marshall Field’s department store in Chicago. The store thought his lectures would lure in trendsetters who might be interested in their new consignment of ultramodern French furniture.

They hated the name “4D Home,” though, and challenged their marketing team to come up with a better one. Young Waldo Warren stayed up all night reading through Fuller’s essays, then created a new word by combining three of Fuller’s favorite words into a new one.

Dynamic.

Maximum.

Tension.

Dymaxion.

Fuller fell in love with the new word. Not only did the 4D House become the Dymaxion House, he also applied the moniker to most of his new projects, and even retroactively applied it to older projects. R. Buckminster Fuller was now a Dymaxion Man creating a Dymaxion World. Every morning in his Dymaxion House he woke from his Dymaxion Sleep, made a log in his Dymaxion Chronofile, took a crap in his Dymaxion Bathroom, then looked up his destination on the Dymaxion Map and drove there in his Dymaxion Car.

In addition to the spiffy new name Fuller also rolled out a line of spiffy new claims about the Dymaxion House.

He said its revolutionary construction would allow it to easily resist natural disasters like earthquakes, floods, fires, and tornadoes as well as man-made catastrophes like infectious disease and gas attacks. (The mechanisms for this were never explained.)

He said it would be entirely self-sufficient:

- Transparent ceiling panels would provide abundant natural light.

- Rainwater would be collected and filtered into something potable.

- The house would come equipped with a special toilet that packaged solid waste into fuel that could be burned for power and heat. (How a single family could produce enough solid waste to power an incinerator was left up to the imagination, though like I imagine they were on a Dymaxion Diet composed entirely of Taco Bell.)

- Any remaining power needs would be covered by solar panels on the roof and the mast, which could function as a circular windmill. (Even though these technologies were only in their infancy.)

He said the house would be “drudge-proofed”, equipped with every labor-saving device known to man: electric ovens, refrigerators, dishwashers, laundry machines, dryers, electric hair clippers, electric toothbrushes, even radios and televisions. These would minimize the time spent on daily chores and allow the residents to spend more time improving their minds.

Even more wild claims! The mattresses would be air beds that could be inflated to any desired pressure! Central air systems would keep the house at a comfortable temperature year round so the residents could go nude 24/7! Windows and doors could be opened with the wave of a hand! The whole unit would retail for a mere $3,000!

Fuller was writing a lot of checks he couldn’t cash. His plans relied a lot on renderite — i.e., materials that did not yet exist, and in some cases, might not exist, like super-strong aluminum, super-light concrete, and miracle plastics. It was not clear that the structural principles he was relying would scale up from the model. The cutting-edge consumer technologies were plausible, but would need to be miniaturized and made interoperable at great cost. That meant there was no way in hell he could ever meet that price point.

His defense was that he was not designing for the present, but for the future. Which may have been true, but doesn’t change the fact that he was banking on technological advances that might never arrive. Ask Mark Zuckerberg how well that’s working out for him.

The all-new all-hype Dymaxion House did catch the interest of the public, who were intrigued but didn’t have much money to spend. Artists and designers were likewise charmed and broke. Captains of industry were still not impressed and also had no money.

What can I say? It was 1929 and the stock market had just crashed. No one was in a position to launch bold new projects.

The only real interest in the Dymaxion House came from Soviet Union, which asked Fuller to create a variant of the design for their collective farms. His only design changes seem to have been scaling everything up proportionately so the house could accommodate more residents, and modifying the power plant to use repurposed tractor engines. The Soviets must have also been disappointed because the Dymaxion Mobile Dormitories never went into production.

That didn’t stop Fuller from continuing to push for the Dymaxion House at his lectures and in the pages of his architecture magazine Shelter. He even rolled out a series of spin-offs, including a Dymaxion Gas Station, a Dymaxion Media Center, and a Dymaxion Tower Garage.

Eventually the Century of Progress International Exposition asked Fuller to create a full-scale model of the Dymaxion House for display at the 1933 World’s Fair. Fuller quoted them a price of $100 million dollars. Later he claimed that he had no desire to do one-offs and this is what it would cost to set up a factory production line and produce the houses at an industrial scale. It’s more likely that he didn’t think he could actually build a Dymaxion House, and quoted the Exposition an outrageous price that would make them go away. That they did… right down the street to George Keck, who was very happy to erect a model home version of his very similar House of Tomorrow.

With no one biting on the Dymaxion House, Fuller was forced to go back to working for other people, first for the American Standard Sanitary Manufacturing Company, and then for the Phelps Dodge Corporation. There he worked on two separate but virtually identical projects that fell under the umbrella of the “Dymaxion Bathroom,” a mass-produced modular bathroom, basically the equivalent to those plug-and-play en suites you sometimes see in older European hotels.

Like the Dymaxion House it would use modern materials and less of them, making it ecologically friendly, could be manufactured industrially with metal stamping equipment, and would have standardized connections to simplify installation. He also replaced everything with its sci-fi equivalent, including vacuum powered toothbrushes, waterless packaging toilets, and a “fog gun” that could steam clean a man with less than a pint of water.

Fuller eventually attached a trailer hitch to the prototype and drove it all over the East Coast. For some reason that lecture tour was a lot less successful than his first. Turns out no one wanted a Dymaxion Bathroom, either.

The Dymaxion [Dwelling | Deployment] Unit

In the late 1930s Fuller was driving through rural Missouri with his good friend, novelist Christopher Morley, when he noticed a row of corrugated steel grain bins along the side of the road. He was struck by their similarity to peasant huts, and went on a mini-rant explaining how they could be turned into housing at a cost of less than $1 per square foot.

Fuller may have only been making idle conversation on the road, but Morley was listening. As it turned out his next novel, 1939’s Kitty Foyle, was a huge hit. Morley sent his friend a small chunk of the royalties and a note exhorting him to get off his butt and go make his pre-fab grain bin homes a reality.

He discovered that the grain bins were part of the USDA’s Ever-Normal Granary Program, part of FDR’s Depression-era agriculture policy — farmers filled the bins, government trucks emptied and returned them, and the grain was sealed away both as a stockpile for future emergencies and to prop up the current market price. These particular bins were made by the Butler Manufacturing Company of Kansas City, Missouri and were known for their quality and reliability.

Fuller traveled to Kansas City to propose a partnership between Butler and his newly formed Dymaxion Corporation. Butler’s board was interested in branching out, and agreed. Fuller immediately went to work drawing plans and building prototypes.

He made relatively few changes to Butler’s basic bin design.

- He cut a door in the side.

- He covered the floor with Masonite tiles and lined the walls with Fiberglass wallboard.

- He replaced the single-piece roof with interlocking panels made out of transparent plastic that let light inside, which could be opened up to provide ventilation.

- Beneath the roof he added a network of wires from which curtains could be hung to subdivide the space.

And that was it.

In August 1940 he unveiled the final prototype of the newly christened Dymaxion Dwelling Unit (DDU). He had converted a 20′ grain bin into a, uh, very cozy 314 sq. ft. apartment. Practically it was a bit less than that, since the curved walls meant that a significant chunk of space was not going to be usable unless you had custom-built furniture. Perhaps aware that was a bit too cozy, Fuller had also added a second bin containing items missing from the initial unit, like a kitchen and a bathroom. (Actually the bathroom was more like a portajohn, with a water tank in the roof and a septic reservoir in the base.) Even that was bit too cozy for the unhoused rural residents the DDU was aimed at. They took a hard pass.

But you know who was interested? The military.

The British military thought the DDUs might be useful as temporary sleeping quarters for soldiers and civilians, and might even be able to be half-buried to serve as bomb shelters. Unfortunately they were currently tied up with some guy named “Hitler” and had to prioritize other projects.

The American military thought the DDUs were ideally suited to be airdropped on remote locations. In April 1941 they had Butler install a DDU at Haynes Point Park in Washington DC. A dean from the University of Michigan lived in it for a few days and pronounced it suitable, but suggested one change: the installation of a few porthole windows to make everything more homey. Fuller complied, the military placed a huge order, and Butler’s factories worked 24/7 to churn out DDUs. By the end of the year thousands of DDUs, which were now Dymaxion Deployment Units, had been shipped out to to U.S. military bases around the world to serve as temporary housing.

In November 1941, the Museum of Modern Art put a DDU on display in its sculpture garden as a work titled “Defense House.” It was Fuller’s greatest achievement to date, tarnished only slightly by the fact that it became a make-out spot for young lovers.

And then on December 7, 1941 the Japanese bombed Pearl Harbor. Military priorities shifted and steel and plastic became reserved for more essential military operations like building liberty ships and airplanes. The DDU was quietly phased out in favor of the simple Quonset hut, which used cheaper materials, was quicker to build, more adaptable in terms of usage, and far more comfortable to live in.

The Second Dymaxion House

Fuller was once again out of a job, but at least this time he had made bank while he could. He went from working with Butler to a job with the Board of Economic Warfare, a position he held for the duration of World War II.

As the war wound down, he turned his attention back to his usual obsessions. Housing was in short supply, and many newly urbanized workers were living in poor conditions. When the war ended not only would those workers lose their jobs in defense production, they would have to compete with for returning GIs for jobs and housing. Clearly what was needed was a massive home-building project that would also be keep industrial facilities running at top capacity.

The obvious solution was the Dymaxion House.

He floated the idea to Herman Wolf of the War Production Board. Wolf was interested, and got him a meeting with Walter Reuther of the CIO and Harvey Brown of the International Association of Machinists. Brown was interested, and got him a meeting with Beech Aircraft in Wichita, Kansas.

Wichita was the perfect example of the problems Fuller had foreseen. Thanks to the war it had become a major manufacturing center for aircraft, and its population doubled in a ludicrously short timeframe. Beech was very aware of the problem and thought the Dymaxion House offered a solution that benefited both the company and the community. General manager Jack Gaty entered into a handshake deal with Fuller.

A few days later Fuller quit his government job, moved to Wichita, and founded a new company, which was either the Dymaxion Dwelling Machines Corporation, or the Dymaxion Living Machines Company, or Fuller Houses, Inc.. What happened to his previous ventures, like Lightful Houses Company and the Dymaxion Corporation? Who knows? Fuller incorporated and disincorporated companies at a whim, and changed their names constantly. It may have been some sort of tax dodge, or a way to get out of contractual obligations.

To raise capital Fuller issued 15,500 shares of stock in the new company, at $10 a share. Some 9000 of these were sold to the general public (but were mostly snapped up by company officers like Herman Wolf), some 1000 were owned by Beech, and the rest were special Class B shares held by Fuller, which allowed him to retain control of the company in spite of being a minority shareholder.

The new company had a contract with the U.S. Army Air Corps, which thought Dymaxion Houses would be ideal for returning veterans, and a partnership with Beech to actually build two prototype units. Fuller recruited six of Beech’s top mechanics and retreated into a abandoned building on the company’s campus to get to work.

A year later he emerged with the first prototype, the “Barwise” house. It was, essentially, the original Dymaxion House model simplified and incorporating some technological advances made in the previous two decades along with some of the lessons he had learned making the DDUs.

- The overall shape went from hexagonal to circular, because Beech was used to manufacturing circular and conical sections for airplanes, and circular pieces made the equations for balancing the sections even simpler.

- At roughly twice the diameter of the DDU it offered a more luxurious 1100 sq. ft. of living space (minus, of course, any space lost to the curved and wedge-shaped bits).

- It was constructed from aircraft-grade aluminum and Plexiglass, to which their government contract gave them ready access. Concrete was no longer required, except for securing the mast into place. Wood was only used for laminate flooring. Fuller maintained this made the house more environmentally friendly because it used fewer trees, conveniently ignoring the huge externalities involved. More importantly the materials chosen provided maximum strength with minimum weight and material usage. The whole house weighed only 3 tons, while a traditional building the same size weighed approximately 150 tons.

- Instead of being built on site the whole building could be compressed into a single shipping tube, small enough to fit on the back of a truck or in the cargo bay of a DC-4. Assembly could be handled by a single worker; no individual piece weighed more than 10 lbs. and no step required unusual tools or more than two hands to install.

- As with his previous projects, the whole building was hung from the central mast and assembled from the top down with walls being attached to the roof pieces and the floor to the completed walls.

- During the construction of the DDU, Fuller had noticed that the temperature difference between the top and bottom (which was suspended slightly above the ground) created a pressure difference and a natural air conditioning. He capitalized on that in the Dymaxion House by installing a ventilator or “gentilator” on the top that turned with the wind and used it to keep air circulating. (It could also lift up to relieve pressure in case the house was ever battered with gale-force winds or tornadoes.)

- Amenities included every modern appliance, a stainless steel fireplace, an HVAC system and centralized vacuum system, recessed lighting with dimmer switches, closets with “o-volving” shelves, and huge windows.

Some of Fuller’s more utopian ideas did have to be abandoned — the house depended on perfectly normal electricity and water connections, rather than being run entirely off recycled grey water, compressed poop pellets, and solar power as he had hoped.

The components only cost $1000 to manufacture, and the whole unit had an estimated retail price of about $6,500, about half the price of the average single-family home. That included shipping, assembly, and a healthy profit for the local dealer.

I have to give it to Fuller. He managed to make something utterly remarkable, a marvel of engineering, and the sort of house the likes of which had never been seen before.

A group of Beech employees and their wives who were chosen to tour the house fell in love with it. And they weren’t the only ones.

The effect on modern architecture of structures now possible will be as catastrophic as the effect of the pioneering work of the early 1900s on the production of the academies. (industrial designer George Nelson)

[The Dymaxion House] may well be the prototype of a new domestic architecture… it will destroy the great architectural dogma that a house is what our great-grandfathers called a house, and that the architect’s sole opportunity is to modify what already exists. (poet Archibald MacLeish)

Occupants of the house will be free of daily drudgery, free to study, to loaf, to play, to develop the million interests that change life to living… [It will] revolutionize daily living for all races and nations. (Frances F. Zala in The Washington Post)

If [Fuller’s] current venture… succeeds… this “dwelling machine” is likely to produce greater social consequences than the introduction of the automobile… A Washington official, who got so sick of hearing from his subordinates about Fuller’s extraordinary house that he finally took a plane to Wichita to see the one Beech Aircraft had built, was taken into the carefully locked building where the prototype was hidden and gasped, ‘My God! This is the house of the future!” (Fortune, April 1946)

There were some criticisms of the house, led by architecture critic Louis Mumford who was no fan of the new architecture. Many of the criticisms focused on issues we’ve already raised — the externalities associated with its manufacture, its unsuitability for different environments, the ridiculous delusion that it would somehow transform the whole of society. The truly cutting comments took issue with the prefabricated nature of the house and how unadaptable it was to changing circumstances. They had a point. It’s not clear how Fuller’s ethos of maximum personal freedom was best expressed by a house which could not be customized in any truly meaningful way. Fuller was never really able to formulate a good counter to this argument, either, and was reduced to grumbling that it would eventually be available in different colors, like a tangerine iMac.

The naysayers were a distinct minority, though. After the house was featured prominently in two issues of Fortune magazine, some 3,500 unsolicited orders were mailed Fuller’s offices. Some of the would-be homeowners even sent in modest down payments. (As remarkable as this achievement was, it didn’t stop Fuller from inflating it by an order of magnitude in later retellings).

It wasn’t just the public, either. Jack Gaty excitedly estimated that with a capital infusion of $10,000,000 the company could set up an assembly line and churn out 60,000 Dymaxion Houses by the end of 1947 and 2,000,0000 Dymaxion Houses by the end of the decade. Investors nearly doubled the value of the company, driving up the price of Fuller House shares to $18. A Philadelphia investor named William Wasserman even purchased 1,000 shares of the company, got himself a seat on the board, and floated an ambitious plan to raise most of the capital by splitting the stock and issuing new shares.

There was just one problem: R. Buckminster Fuller.

Fuller declared that the Dymaxion House was not yet ready to bring to market, which was almost certainly true. Not only were there kinks to be worked out through tinkering, there were likely larger problems with the design that would only become obvious with time. He also declared that the world was not yet ready for the Dymaxion House, either. He hadn’t even designed the special futuristic furniture he intended to ship with the house. More than that, he intended to revamp the entire construction industry from the ground floor up — everything from building codes to manufacture to delivery and deployment would need to be completely redesigned by his brilliant mind. He estimated he would have it all figured out and ready to go by, oh, 1952 or so.

Beech and the investors were flabbergasted. They tried to persuade Fuller to strike while the iron was hot, but he refused to dilute the purity of his vision and rush a product to market.

Thanks to the Class A shares which gave him extra votes, no one could force him to change his mind even if they held every other share in the company. He eventually bought out Wasserman to make him go away, the other investors lost interest in the project, and a disgruntled Beech canceled its partnership.

By the end of 1947 the company was down to one employee and no commercial projects. The predicted housing shortage turned out to be a short-term issue and not a long-term one. The establishment of the post-war American empire and the start of the Cold War kept industrial factories on-line reducing the need for new make-work projects.

No one needed Dymaxion Houses, and other than a few futurists, no one wanted one either.

A few months later the company was dead. Fortune magazine had the final word, mournfully noting that “What happened to Dymaxion demonstrates the unbridgeable gap that sometimes exists between an idea and its fulfillment.” (Fortune, May 1848).

Later Works

After the failure of the second Dymaxion House, Fuller stopped trying to be an architect and instead started positioning himself as a visionary. It was a much more rewarding life because he could never disappoint, only be disappointed.

There was plenty of money in it, too. Like-minded technocrats were always happy to throw some money at Bucky Fuller to make it seem like they were thinking big about the future. In essence he became mid-century corporate America’s equivalent of Shingy, an endless fountain of lofty sentiment with nothing substantive behind it.

He did occasionally return to the problem of housing. Working with students at Chicago’s Institute of Design he designed “The Standard of Living Package”, a shipping container packed full of flat-pack furniture which could be turned into very modest apartment for a family of six. It was an interesting thought experiment but treading ground that had already been covered by the Dymaxion Dwelling Unit, the Quonset hut, and the mobile home.

He experimented with geodesic domes, and even managed to get a few built. I should clarify that while he is frequently credited with inventing the geodesic dome in 1948, it had actually been invented in the 1920s by engineers working for Zeiss, the planetarium people. Fuller merely popularized the concept and consciously chose to not correct anyone who assumed he had invented it.

In the 1960s and 1970s he unveiled some truly megalomaniacal urban planning concepts, including several arcology-style suburbs for the city of Toronto and a giant “Tetrahedron City” that would float off the coast of Japan. As usual these plans were big on ideas and short on details.

He died on July 1, 1983. An obituary in the Philadelphia Inquirer was far kinder to him than he probably deserved.

He began anticipating the needs of mankind in 1927 and after three decades of being ignored, or at best being viewed as an amiable crackpot, he became during the 1960s a hero of American culture.

Why You Don’t Live in a Dymaxion House

So, let’s ask a very simple question: why don’t you live in a Dymaxion House? They’re unusual, to be sure, but there are a lot of people out there in unusual housing situations. Surely there’s a hipster somewhere who would be living in a Dymaxion House if such a thing were practical.

The answer is R. Buckminster Fuller. Simply put, he didn’t care whether anything he designed ever got built.

Fuller’s defenders will say that the Lightful Towers and the 4D House were only concept drawings, and the first Dymaxion House was only a model. That didn’t stop them from being unrealistic in ways that made them almost impossible to build.

Fuller had more success with the Dymaxion Dwelling Units (or Dymaxion Deployment Units, whichever you prefer) but they were also the least ambitious project he ever undertook. In the end they had about the same level of utility as a mobile home with a bunch of odd quirks that made them off-putting.

And as for the second Dymaxion House, Fuller killed the project because he was willing to let the perfect be the enemy of the good, because he was too attached to the dream to turn anything into reality. Or maybe he realized that the Dymaxion House was going to flop hard and decided to kill the project before it ruined his reputation as a visionary. Better to be Bucky Fuller than Preston Tucker, right?

If you’re not following along, let me tell you about the ultimate fate of the second Dymaxion House.

When Fuller Houses went under, the Barwise prototype and the parts of the second, never-completed “Danbury” prototype were purchased by company stockholder William H. Graham, who Frankensteined them together to make his own Dymaxion House in the suburbs of Wichita.

Graham quickly discovered that the Dymaxion House did not live up to the hype. The gentilator did not work as promised, meaning that the house was uncomfortably warm during the day; there were large gaps in the roof structure that let in drafts and leaks; the plastic windows delaminated in the sunlight; and the aluminum panels began to corrode around the steel rivets that held them into place; the interior systems also required quite a bit of maintenance than was promised. He abandoned his plans to move into the house and turned it into an ultra-modern playhouse for his children instead.

Now, the Grahams did make some changes to the structure. They put it on a conventional foundation, eliminated the mast, and replaced the gentilator with a more conventional air conditioning unit. According to Fuller, these changes were made before the Grahams experienced the house and essentially ruined it. The Grahams maintain the changes were made after they experienced the house, in an attempt to remedy its deficiencies.

For some reason, I am more inclined to believe the word of a young family that tried living in an untested prototype than the word of a grumpy curmudgeon who didn’t want anyone besmirching his genius.

After the Graham children grew up the house was abandoned. It somehow managed to survive a 1964 tornado with only minimal cosmetic damage, only to have far worse cosmetic damage when it was painted pink to look like a giant boob and used to advertise a local strip club. Its only residents were a family of ornery raccoons.

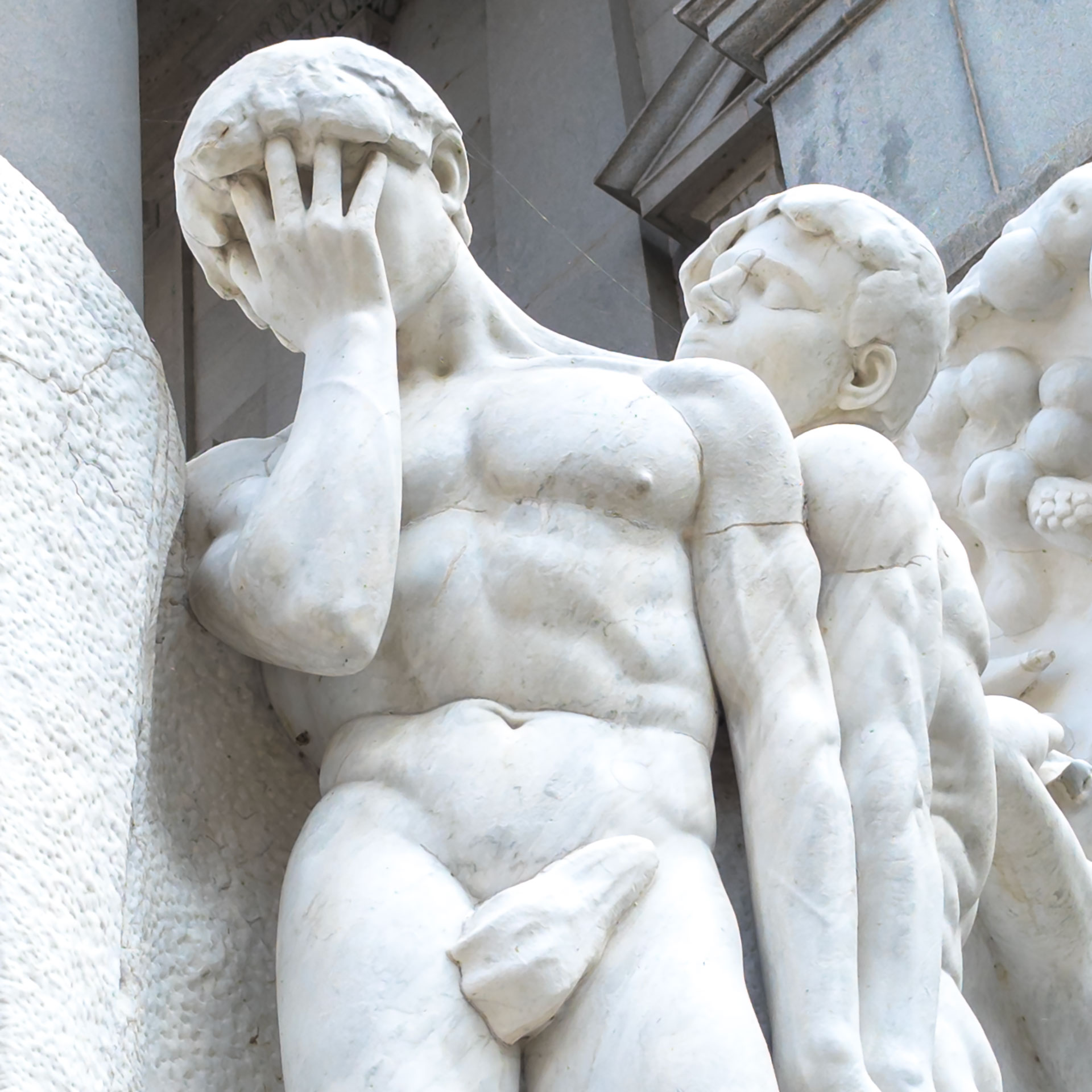

In 1988 the Grahams sold the structure to the Henry Ford Museum, which among other things collects famous people’s houses and workshops and relocates them to its model Greenfield Village on the outskirts of Dearborn, Michigan. The curators lovely restored the house to the original appearance of the Barwise prototype, and even fabricated an new gentilator for the roof. In 2001 it went back on display… inside the museum, because it was too fragile to be exposed to the elements.

For a while you could get guided tours of the interior from docents posing as 1940s real estate agents. That practice seems to have come to an end during the pandemic, and when I visited in 2022 you could only walk around the outside and peer in the windows. It looks like they may have reversed it recently, though, so if you find yourself in Dearborn you should definitely go check it out because it is a marvel of modern engineering. And then go around the corner to check out one of the original Wienermobiles.

For God’s sake, though, don’t try to live in it. Because it’s still a pretty terrible house.

Errata

(All corrections from the errata have been incorporated into this article, but not into the published audio.)

Connections

Le Corbusier was also highly influential on the life of another utopian dreamer, Paul Otlet (“Steampunk Google and the World City”), who sought to catalogue all of the world’s knowledge and build a fabulous city to house a world government.

Fuller’s assumption that aluminum would not corrode or require maintenance would have been news to the aeronautical engineers who designed the U.S. Navy’s rigid airships (“Air Crash Museum”), several of which crashed in part due to weathering and structural stress on their exposed aluminum supports.

Other attractions at the Henry Ford Museum and Greenfield Village include a cabin that once belonged to George Washington Carver, who helped popularize peanut butter even if he didn’t actually invent it (“Crunchy Or Wrong”).

Supplemental Material

Sources

- Anker, Peder. “Buckminster Fuller as Captain of Spaceship Earth.” Minerva, Volume 45, Number 3 (December 2007).

- Bergdoll, Barry and Christensen, Peter. Home Delivery: Fabricating the Modern Dwelling. New York: Museum of Modern Art, 2008.

- Columina, Beatriz. “DDU at MOMA.” ANY: Architecture New York, Number 17 (1997).

- Eastham, Scott. “Global Village or Global Pillage? The Ambivalent Centennial of Lewis Mumford and Buckminster Fuller.” Australasian Journal of American Studies, Volume 15, Number 1 (July 1996).

- Fitch, James Marston. “The Rise of Technology: 1929-1939.” Journal of the Society of Architectural Historians, Volume 24, Number 1 (March 1965).

- Gorman, Michael John. Buckminster Fuller: Designing for Mobility. Milan: Skira Editore, 2005.

- Hays, K. Michael and Miller, Dana. Buckminster Fuller: Starting with the Universe. New Haven, CT: Yale University Press, 2009.

- Keats, Jonathon. You Belong to the Universe: Buckminster Fuller and the Future. Oxford: Oxford University Press, 2016.

- Lorance, Loretta. Becoming Bucky Fuller. Cambridge, MA: MIT Press, 2009.

- Mumford, Lewis. The Myth of the Machine: Technics and Human Development. New York: Harcourt, Brace, & World, Inc., 1962.

- Picon, Antoine and Robbins, Miranda. “Fuller’s Promised Land.” ANY: Architecture New York, Number 17 (1997).

- Rappaport, Nina. “Observations on Fuller.” Log, Number 13/14 (Fall 2008).

- Schiffer, Michael Brian. Spectacular Flops: Game-Changing Technologies That Failed. Clinton Corners, NY: Eliot Werner Publications, 2019.

- Sellers, William R.; Pesce, Augustus J; and De Angelis, Louis. “Aesthetics in Educational Architecture.” Journal of Education, Volume 152, Number 2 (December 1969).

- Sieden, Lloyd Steven. Buckminster Fuller’s Universe: His Life and Work. Cambridge, MA: Perseus Publishing, 1989.

- Vidler, Anthony. “Whatever Happened to Ecology? John McHale and the Bucky Fuller Revival.” Log, Number 13/14 (Fall 2008).

- Wong, Yunn Chii. “Fuller’s Corporate Soul.” ANY: Architecture New York, Number 17 (1997).

- Zung, Thomas T.K. (editor). Buckminster Fuller: Anthology for the New Millennium. New York: St. Martin’s Press, 2001.

- “‘Dymaxion’ house has ultra design.” Washington Evening Star, 26 Apr 1929.

- “Fuller’s House.” Fortune, Volume 35, Issue 4 (April 1946).

- “What became of the fuller house?” Fortune, Volume 37, Issue 5 (May 1948).

- “Richard Buckminster Fuller.” Design Quarterly, Number 74/75 (1969).

- “Buckminster Fuller.” Wikipedia. https://en.wikipedia.org/wiki/Buckminster_Fuller. Accessed 1/31/2024.

- “Dymaxion House.” The Henry Ford. https://www.thehenryford.org/visit/henry-ford-museum/exhibits/dymaxion-house/ Accessed 1/31/2024.

- “Dymaxion House.” Wikipedia. https://en.wikipedia.org/wiki/Dymaxion_house Accessed 7/21/2023.

Links

Categories

Tags

Published

First Published:

Last Edited: